Challenge 1

Toyota Industries Corporation

Industrial Development in Aichi

Prefecture through Digital Transformation

- Solving Social Issues through the Use of Autonomous Mobile Robot "AiR" -

Prefecture through Digital Transformation

- Solving Social Issues through the Use of Autonomous Mobile Robot "AiR" -

Future World

How to perceive the future

Our company has traditionally been involved in the business areas of automobiles, material handling equipment, and textile machinery.

Today, society and lifestyles are being transformed by the emergence of CASE and MaaS surrounding mobility, and the further expansion of e-commerce and other online activities.

Under such circumstances, to achieve sustainable growth, we need to proactively take account of emerging social needs and technologies and envision how to provide value beyond the framework of existing businesses.

Vision

What is the purpose of Co-Creation?

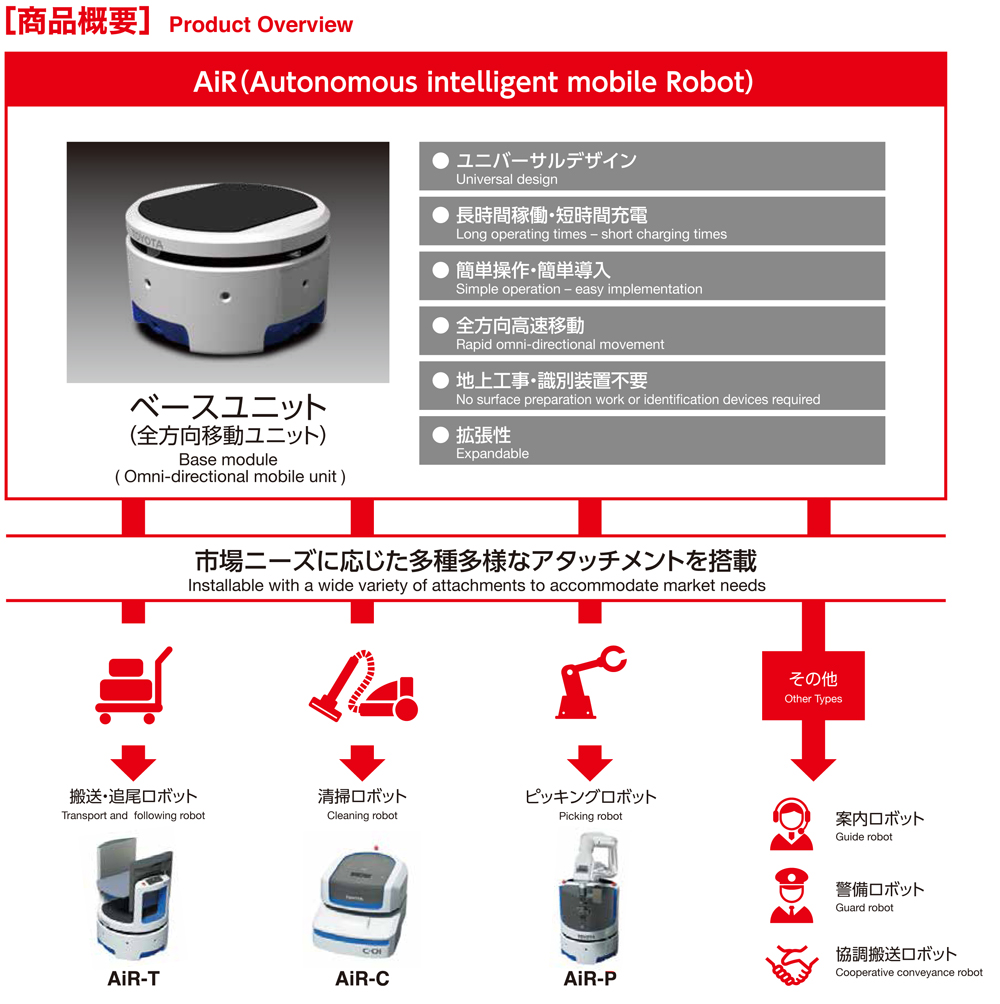

In this Challenge, we would like to co-create with external parties through utilizing the autonomous mobile robot "AiR" developed by Toyota Industries Corporation.

Background

- Our strength lies in manufacturing. In our material handling equipment business, we have been providing products and solutions to warehouses and factories. In the nature of things, as to AiR, we have also been focusing on deploying AiR to warehouses and factories. With the rise of digital solutions and the shortage of human resources, the number of industries that need to utilize robots and ICT is growing. Therefore, we would like to call for novel ideas that no one has noticed yet, targeting a wider range of areas while keeping in mind the logistics and manufacturing sites where our company's strengths can be utilized.

- Example 1: Digital transformation (DX) of logistics and manufacturing sites

- Example 2: Achieving inclusion of the elderly, people with disabilities, and foreigners

- Example 3: Improving the happiness of patients in medical and nursing care settings, medical /nursing care workers, and the government/prefectural/city

- Example 4: Improving customer satisfaction in the service industry such as retail and restaurants

- Other free suggestions (free themes)

We call for ideas on how AiR can be used in various industries and situations, not limited to the examples above.

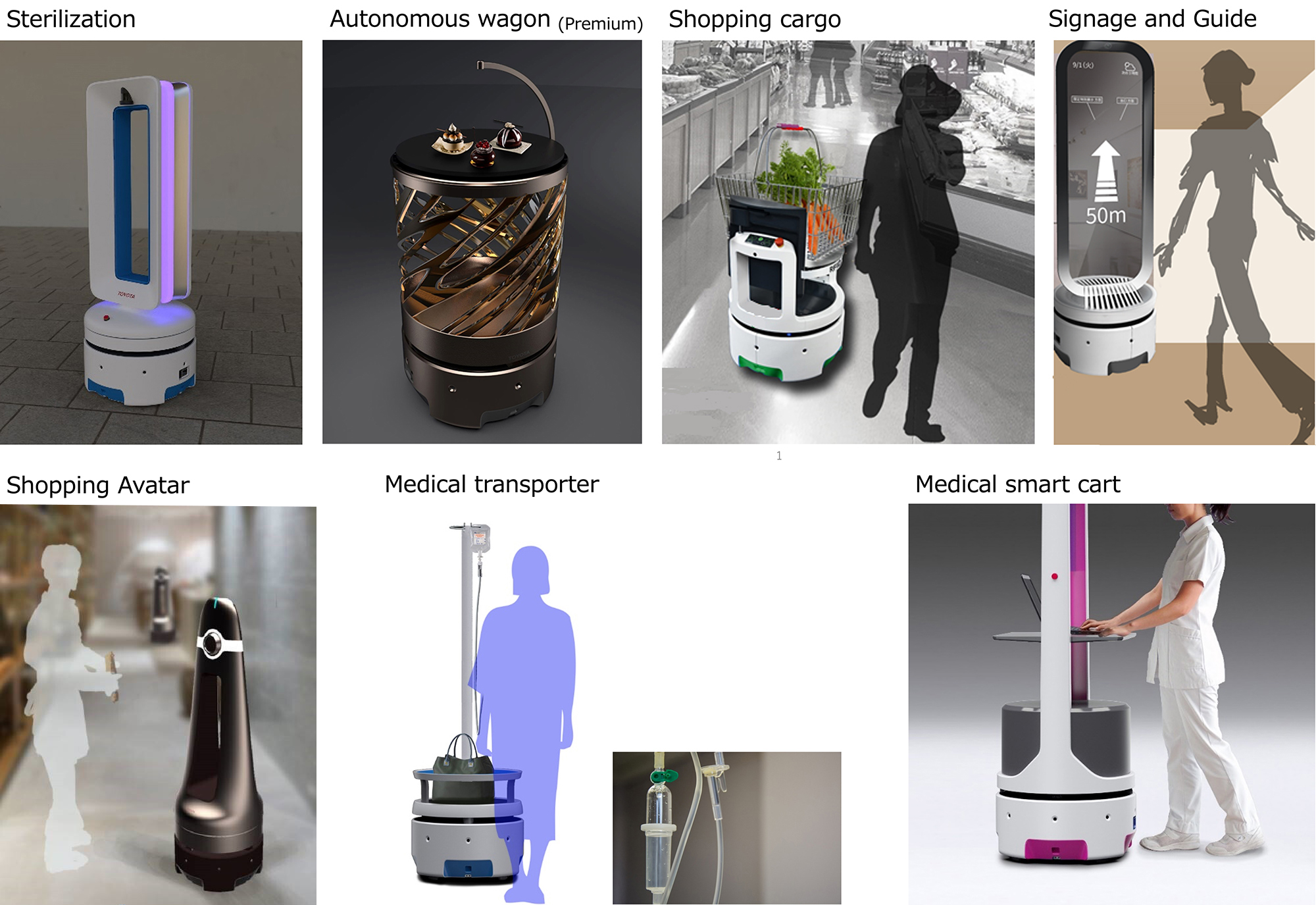

Examples of ideas we have considered so far

Intellectual Capital

What is the potential that can be tapped for the future?

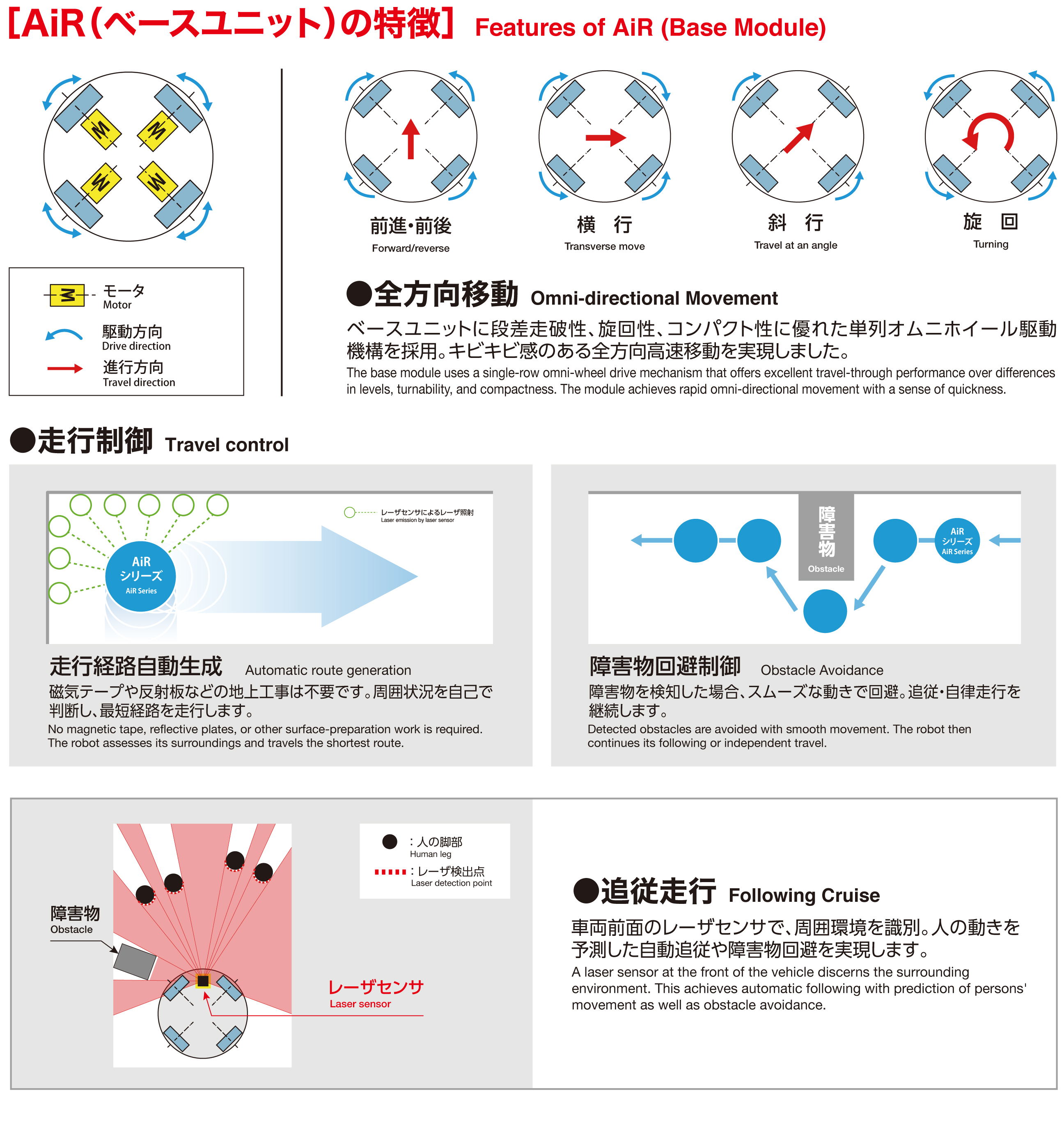

In this Challenge, Toyota Industries Corporation intends to utilize the following strengths related to AiR.

- A wide variety of hardware and software can be considered for integration with AiR.

- We can provide AiR machines for evaluation use.

- Knowledge and expertise in robot control technology

- Past experience and knowledge gained from demonstration experiments using AiR

- Foundations of manufacturing cultivated over many years of history

- Domestic and overseas customer base

Potential Partner

What kind of partners do you want to co-create with?

We welcome all partners who have a good grasp of all kinds of social issues and needs in Japan and overseas and are willing to use AiR to create innovative ideas and solutions to solve them.

- In the application, please describe what roles and functions you expect AiR to play in the co-creation model you wish to discuss with us. Please note that we do not expect any major modification of the basic functions of AiR.

You may be requested to conclude a separate agreement with us regarding subjects such as the handling of intellectual property rights during the challenge period.

Asset

We assume the provision of our autonomous mobile robot (AMR) "AiR", and its related technical know-how, support and so on.

(Subject to the separate agreement with us, depending on the contents of your idea and progress of the co-creation.)

Benefits

Benefits of passing the document screening

- Consideration of conducting a demonstration experiment

Co-creator

Kimihito Tanaka

Group Manager

LX Group 1

LX office

Automation and Robotics Project

R&D Center

TOYOTA Material Handling Company

After working on the commercialization of AI technologies at a telecommunication company, he joined Toyota Industries Corporation in 2020. He received an MBA from the University of Manchester, UK.

Kenta Nakauchi

Assistant Chief Engineer

L3 Engineering Office

Automation and Robotics Project

R&D Center

TOYOTA Material Handling Company

After engaging in the development of car air-conditioning compressors and R&D works at the head office, he has been in charge of the development of autonomous mobile robots in TOYOTA Material Handling Company since 2013.

Tadayuki Yakushi

Group Manager

Design Group

Technology Planning Office

Global Product Planning Dept.

R&D Center

TOYOTA Material Handling Company

After working on the design of Toyota brand vehicles such as YARIS, and advance development works of Lexus cars at a European design studio, he has been engaged in the design of forklifts and other material handling equipment since 2006.

He has received numerous awards, including the Good Design Award (Japan), the German iF Award, and the Reddot Award.

Kayoko Miyagawa

Project Manager

Business Planning Office

Corporate Planning Department

After working in the Legal Department (contract review, M&A and other projects, compliance activities, etc.), she has been in charge of new business planning since 2018.